3 advantages of hardness testing|hardness testing meaning : traders Micro hardness test is used for measuring the hardness of thin or small objects, complicated shapes, surface coatings, and plantings. This testing method can also perform for depth identification of case-hardened layers, . WEB13 de jan. de 2017 · Top Shanghai Fun Activities & Games: See reviews and photos of fun activities & games in Shanghai, China on Tripadvisor.

{plog:ftitle_list}

Resultado da 1. ⭐⭐⭐⭐⭐Publica so tem novinhas br. O carrinho que transportava os atletas dos 200m rasos se chocou a caminho da arena👍 de🇺🇲 provas, em .

What Are the Benefits of Hardness Testing? Hardness testing offers a significant measure of material characteristics with several advantages: Simplified Measurement: Automated hardness testing machines streamline the process, making it relatively straightforward to . In this article, we briefly explained the importance and application, advantages and disadvantages of Rockwell hardness test. We also introduce the Rockwell test with .

why hardness testing is necessary

All in all, a hardness test is a crucial test that you must adopt in ensuring that your product meets the stated quality specifications. At Willrich Precision Instrument, we provide a . Micro hardness test is used for measuring the hardness of thin or small objects, complicated shapes, surface coatings, and plantings. This testing method can also perform for depth identification of case-hardened layers, .Hardness test methods in the macro range include Brinell, Vickers and Rockwell. Hardness testing in the low-load range applies when the test load falls between an interval of 0.2 kgf and 5 kgf (test load ≥ 0.2 kgf and < 5 kgf). The most .The application of hardness testing enables you to evaluate a material’s properties, such as strength, ductility and wear resistance, and so helps you determine whether a material or .

The hardness of a material enables it to resist bending, scratching or cutting. The most common tests are the Rockwell, Brinell, & Vickers hardness tests.

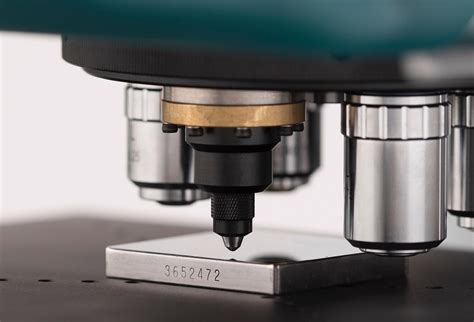

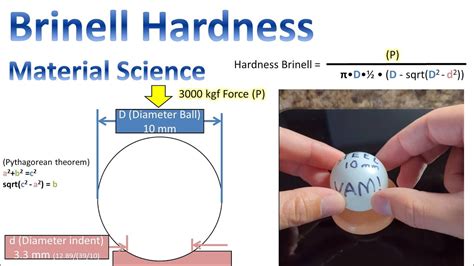

Hardness testing is a mechanical test that measures a material’s resistance to indentation, scratching, or abrasion. The test is performed by applying a specific force on the surface of the material using a standardized . Fundamentally, hardness testing determines the resistance a material exhibits in response to the permanent deformation of another material’s penetration. If I take a piece of metal and rub something else against it, I . Brinell Indentation Diagram. In the standard method of the Brinell Hardness Test, we use 250 to 500 kg of load for soft material and 500 to 3000 kg of load for hard material such as steel and iron.The Vickers hardness test is ideal for testing of all metals and is therefore the method with the widest range of application. The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – .

The Brinell hardness HBW results from the quotient of the applied test force F (in newtons N) and the surface area of the residual indentation on the specimen (the projection of the indentation) after removal of the test force (see Brinell . Hardness testing is a crucial aspect of metallurgy, as it provides valuable insights into a material’s mechanical properties and overall quality. There are various methods available for measuring hardness, each with its own set of advantages and limitations. In this blog, we’ll delve into the Vickers Hardness Test and discuss when it’s best to use this method over other .

The Vickers hardness testing method offers advantages such as a small indentation size, accurate hardness measurements, and applicability to a wide range of materials. Series measurements or mappings are very often carried out using this met-hod. However, it may not be suitable for very soft or highly textured materials, while alternative .The Vickers hardness tester offers several advantages over other hardness testing methods, such as broad applicability to all materials, high accuracy, and others. Please check out below. 1. Broad Applicability to All Materials. Vickers hardness testing suits various materials, including metals, ceramics, and some polymers. The hardness test is a way to assess the quality of a material, determine its properties, and evaluate its suitability for a specific application. What is Hardness Testing? Hardness testing is a mechanical test that measures a material’s resistance to indentation, scratching, or abrasion. The test is performed by applying a specific force on .

Regular macro hardness is an application of test when the surface area is large, and the indention is deep. Superficial macro hardness is applied with a large surface area, but penetration is shallow in this test. 3. Advantages and Disadvantages of Macro Hardness Testing. Advantages of Macro Hardness Testing The Leeb Hardness Test, also known as the rebound hardness test, measures hardness by analyzing the rebound of an indenter, rather than the size of an indentation. It is portable and ideal for on-site testing of large and heavy components, offering a non-destructive method that causes minimal damage to finished parts and coatings.profiles. The Rockwell test is the most popular indentation hardness test and is used in a wide variety of applications. Advantages of the Rockwell Test There are several reasons for the popularity of the Rockwell test. The test itself is very rapid. On a manually operated unit, a Rockwell test takes only five to ten seconds,The Leeb method is a quick and portable hardness test method, which is determined by the ratio of rebound velocity to the impact velocity of a moving impact body. It is best applied to solid parts of the object for example casting and forgings. In the article, we include the advantages and disadvantages of Leeb method in details.

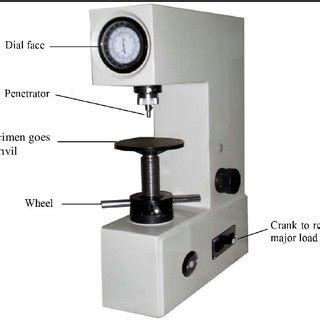

The Rockwell hardness test involves making an indentation on the test material. The indenter is either a conical diamond or a steel ball. Indenter ball diameters range from 1/16 to 1/2 inches and are chosen based on the test parameters. .A Vickers hardness tester. The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. [1] The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter .What is the Standard for the Rockwell Hardness Test? Advantages and Disadvantages Of the Rockwell Hardness Test. Advantages Of Rockwell Hardness Test. 1. Versatility and Wide Applicability; 2. Quick and Efficient; 3. Ease of Use; 4. Wide Range of Hardness Scales; 5. Surface Preparation Flexibility; 6. Non-Destructive Testing; 7. Adaptability to .All information about the Vickers hardness test Test procedure Sample request for the Vickers method Vickers hardness Hardness Discover now. . The Vickers method has the following advantages: The Vickers method can be .

The types of macro hardness tests are the Rockwell hardness test, the Brinell hardness test, and Vickers hardness test. Answer and Explanation: 1 There is various type of advantages associated with hardness testing.

The quotient of the test force divided by the surface area of the indentation is the Vickers hardness number. Vickers hardness value calculation formula: HV=constant × Test force/indentation surface area, where HV is the . An operator performing a Rockwell hardness test. (Source: Arkansas Department of Transportation.) The Rockwell hardness is calculated using the following formula: Rockwell Hardness, HRC = [0.2 – permanent depth of indentation (mm)] x 500 . Knowing the advantages and disadvantages of each test is key to determining which method is the most .

Advantages of Micro Hardness Tester. Micro hardness testers offer numerous advantages in the field of material analysis and characterization. In this chapter, we will explore the key benefits of using micro-hardness testers and how they contribute to accurate and . This testing of heterogeneous microstructures is a big advantage of Brinell hardness testing. In principle, however, it is only suitable for soft to medium-hard materials. Figure: Testing of heterogeneous materials

how hardness testing works

Brinell hardness test is an indentation hardness test. It uses a hard spherical ball (usually around 10mm in diameter). An applied force (a typical test will use 3,000 kilograms) pushes the ball against the surface of the material for a set amount of time (between 10 – 30 seconds, known as the dwell time).The Knoop method has the following advantages. The Knoop method can be used with any and all materials and test specimens, from soft to hard, as the procedure covers the entire hardness range. There is only one type of indenter, which can be used for all Knoop methods.Leeb Hardness Test. The Leeb hardness test is a non-destructive and portable method used primarily for metals. It involves a spring-loaded end with a spherical or conical indenter. The end that makes contact with the material is released, and the rebound velocity is measured after striking the material's surface.

The advantage of Rockwell hardness testing is the relatively short testing time and good automation capability, as the measured values are determined directly from the indentation depth without optical measurement under a microscope. This process is therefore particularly suitable for automated production.The best way to mobile hardness testing. The SONODUR 3 provides two different technology standards for hardness testing: The UCI method (Ultrasonic Contact Impedance) and the Leeb method. . Your advantages: Proven UCI methods: According to the current standards DIN 50159 1,2-2021 and ASTM A1038 2019.

3.2 Conducting the Test. Positioning the Sample: Secure the material sample in the testing machine.; Selecting the Indenter: Choose the appropriate ball diameter based on the material hardness.; Applying the Load: Gradually apply the specified load using the machine.The load should be maintained for a predetermined dwell time, usually between 10 to 15 seconds.The Brinell Hardness Tester, a widely used method for assessing material hardness, offers several advantages and limitations that are important to consider when performing hardness testing. Understanding both the strengths and weaknesses of the Brinell Hardness Test is crucial for obtaining accurate and reliable hardness measurements.

mcs universal testing machine

hardness testing standards explained

webУ MetroOpinion ми робимо опитування дуже легкими для роботи вдома. У нас є одні з найкращих опитувань на ринку. Ви можете побачити, що ви заробите, у кожному запрошенні на опитування.

3 advantages of hardness testing|hardness testing meaning